Top gearbox cvt Secrets

Top gearbox cvt Secrets

Blog Article

It can be the kind of shaft that is saved parallel to your input shaft in a continually variable transmission, similar as enter shaft Additionally, it has splines in excess of its cross-section and is mounted upon by output pulleys.

Imagine for a minute driving a car or truck that only had very first gear or a car or truck that only experienced third gear. The previous motor vehicle would speed up properly from a whole cease and would manage to climb a steep hill, but its major velocity can be limited to only a few miles an hour or so. The latter car or truck, Then again, would fly at 80 mph down the highway, nevertheless it would have Nearly no acceleration when getting started and wouldn't have the capacity to climb hills.

The increase of the electrical bicycle has brought a reappraisal on the CVT as an even better Resolution for an ideal generate train set up compared to gearing techniques historically used on human driven bicycles.

Identical as transferring enter pulley but unlike shifting input shaft, this shaft is placed on the right-hand aspect around the output shaft.

Some cone CVT designs use two rollers.[23][24] In 1903, William Evans and Paul Knauf applied for the patent over a consistently variable transmission making use of two parallel conical rollers pointing in reverse directions and connected by belts that would be slid along the cones to range the transmission ratio.

• Superior fuel intake than a regular automated transmission as being the CVT will be able to maintain the car in its ideal ability range despite velocity

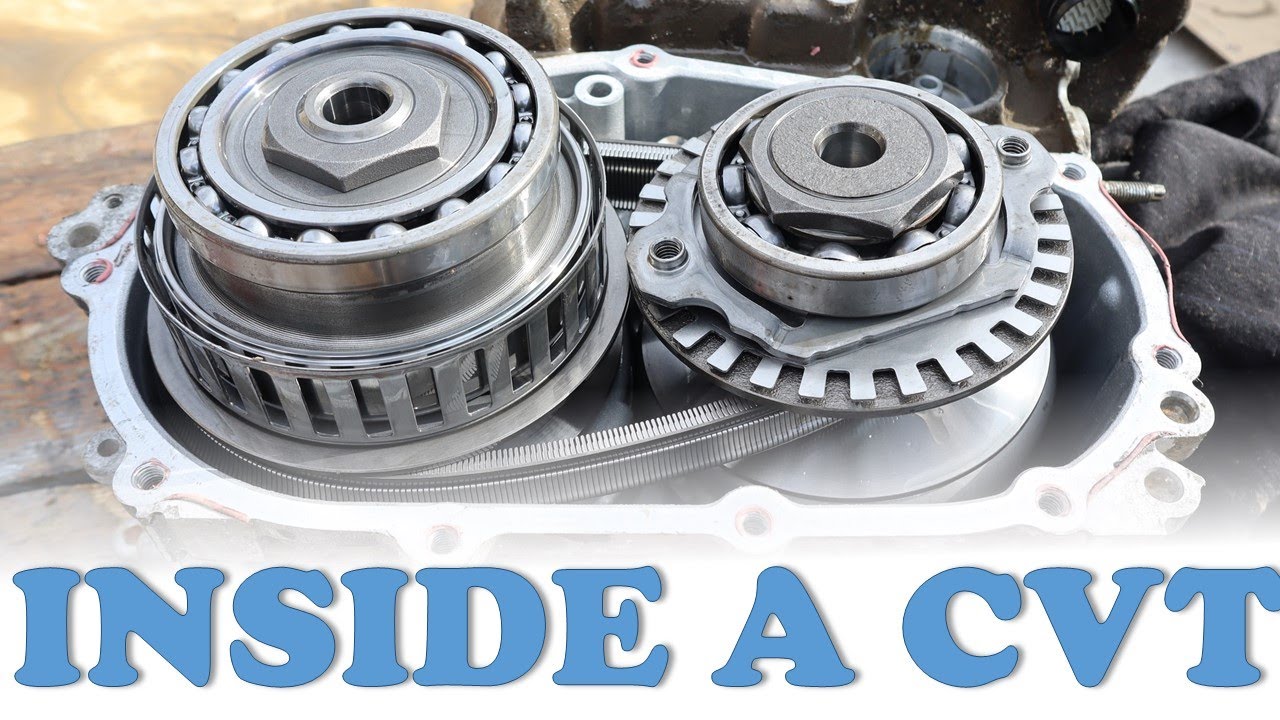

In Cvt pulleys play a significant position because the conical form pulleys built-in in excess of input and output shafts are The main reason for constantly variable transmission’s ongoing n-amount of speed and kit ratios, resulting from different cross section of these conical pulleys a number of torque and pace ratios are acquired.

Inside a Cvt transmission a v-shaped metallic (rubber in some case) chain or belt is used to transmit electrical power from enter pulleys on the output pulleys as this belt or chain is wrapped over both conical input and output pulleys pairs as well as V-shape of this belt or chain enable it to be feasible to shift gears from high torque towards the high velocity.

[3] The V-belt has to be incredibly rigid from the pulley's axial path for making only brief radial movements when sliding out and in from the pulleys.

You are able to listen to this once you’re driving; as an alternative to the motor making an audible fall in revs amongst up-alterations, a CVT gearbox tends to supply a constant drone as the vehicle quickens.

A traditional computerized gearbox takes advantage of gears to match motor velocity to road velocity. At low speed, the engine turns a small gear and that is linked to a bigger gear that turns the wheels through other transmission elements.

This second sort of layout is comparable in theory into a pulley-based mostly CVT but nevertheless a bit diverse. The sections included Allow me to share electric power rollers terus ke sana and discs, in place of pulleys and belts. There's two disks associated with two rollers in between.

In a standard CVT, You can find an enter pulley that is linked to the motor crankshaft via a torque converter (or clutch pack) and an output pulley that sends electrical power towards the wheels. A belt (or chain) connects the two pulleys, which might alter their diameters to supply an infinite quantity of gear ratios. Without any gears, the stepless transmission allows for smoother acceleration and performance, while being smaller in size in comparison with transmissions that do have gears. This can be a excellent set of qualities for Daihatsu, because it allows for much better packaging in its kei and compact cars. But you will find downsides to a traditional CVT

Therefore the regular automatic is to some degree compromised as the motor has to choose from just a few gear ratios. The reason This is often fewer than great is mainly because engines are ideal optimised to run only in a slender rev selection. The wider rev range the motor should function over, the greater compromises the designers must make.